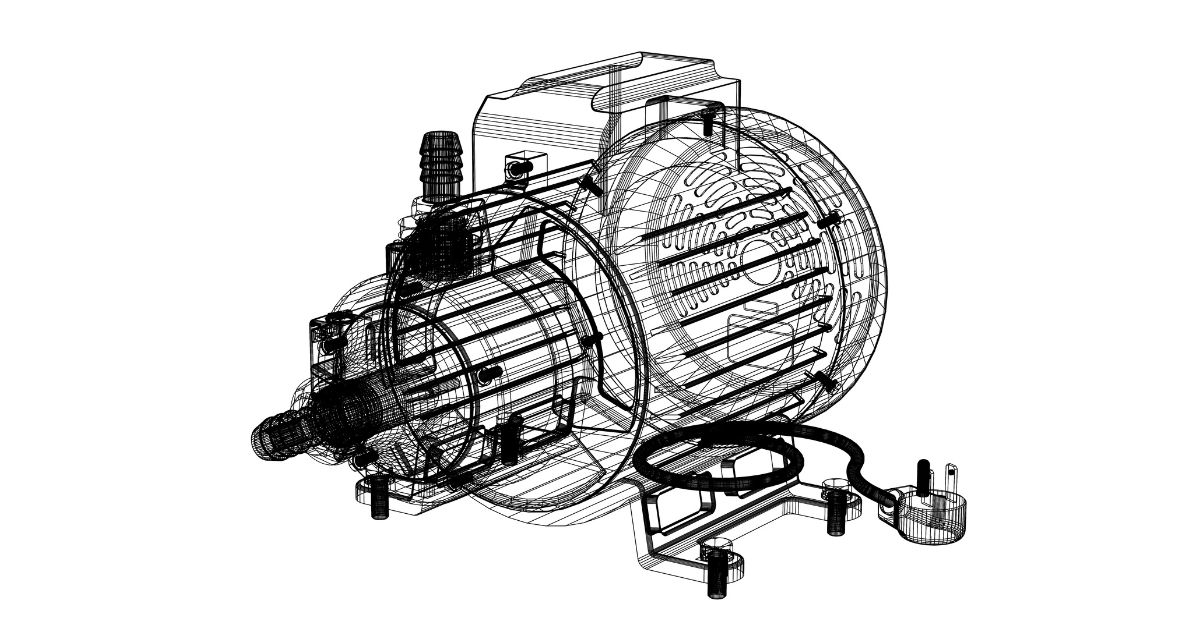

Choosing the appropriate electric motor for your machine is a crucial decision that significantly impacts its performance, efficiency, and overall functionality. Electric motors play a vital role in powering a wide range of industrial and commercial machines, from conveyor belts to pumps and manufacturing equipment. In this guide, we will explore the key factors to consider when selecting an electric motor to ensure optimal performance and reliability for your specific application.

- Understand the Application Requirements:

The first step in choosing an electric motor is to thoroughly understand the requirements of your application. Consider factors such as the load type (constant or variable), duty cycle, speed, torque, and environmental conditions. Additionally, identify any special features or characteristics that may be necessary for your machine to operate effectively.

- Types of Electric Motors:

There are various types of electric motors available, each designed for specific applications. Common types include:

a. AC Motors: – Induction Motors: Simple, rugged, and cost-effective for general applications. – Synchronous Motors: Ideal for applications requiring precise speed control.

b. DC Motors: – Brushed DC Motors: Simple and inexpensive, suitable for certain applications. – Brushless DC Motors: Efficient, reliable, and low maintenance, ideal for high-performance applications.

c. Specialized Motors: – Servo Motors: Provide precise control over position, velocity, and acceleration. – Stepper Motors: Offer precise control without the need for feedback systems.

- Consider Motor Efficiency and Size:

Efficiency is a critical factor when selecting an electric motor, as it directly affects operating costs and environmental impact. Look for motors that comply with energy efficiency standards and regulations. Additionally, consider the physical size and weight of the motor, ensuring it fits within the available space and meets any weight limitations.

- Evaluate Power Supply and Voltage:

Check the power supply requirements for your machine and select a motor that operates within the specified voltage range. It’s essential to ensure compatibility and prevent damage to the motor or other components of the machine.

- Assess Environmental Conditions:

Consider the environmental conditions in which the motor will operate. Factors such as temperature, humidity, and exposure to dust or corrosive substances can impact motor performance and lifespan. Choose a motor that is designed to withstand the specific environmental challenges of your application.

- Budget Considerations:

While it’s crucial to prioritize performance and reliability, budget constraints are a reality. Evaluate the overall cost of ownership, including purchase price, energy efficiency, maintenance requirements, and expected lifespan. This holistic approach will help you make an informed decision that aligns with both your technical and financial considerations.

Conclusion:

Choosing the right electric motor for your machine involves a careful analysis of the application requirements, motor types, efficiency, size, power supply, environmental conditions, and budget constraints. By considering these factors comprehensively, you can make an informed decision that ensures optimal performance, longevity, and efficiency for your specific machine application.